Unraveling the Wires: The Crucial Roles of Encoder and Resolver Cables in Industry

Introduction

In the dynamic landscape of industrial automation, precision and accuracy are paramount. Encoder and resolver cables play a pivotal role in ensuring the seamless operation of machinery, providing crucial feedback that enables precise control and monitoring. These cables are the unsung heroes behind the scenes, facilitating the exchange of information between devices and control systems. In this article, we’ll delve into the uses of encoder and resolver cables in various industrial applications and explore their significance in achieving optimal performance.

Understanding Encoders and Resolvers

Before we explore the applications, let’s briefly understand what encoders and resolvers are:

-

Encoders:

- Encoders are devices that convert mechanical motion into electrical signals.

- They are commonly used to measure the position, speed, and direction of rotating components in industrial machinery.

- Two main types of encoders are incremental and absolute, each serving specific applications.

-

Resolvers:

- Resolvers are devices used to measure the angular position of a rotating shaft.

- They operate based on electromagnetic induction principles and are known for their robustness in harsh environments.

- Resolvers provide continuous, smooth feedback over 360 degrees of rotation.

Encoder Cables in Industrial Applications:

-

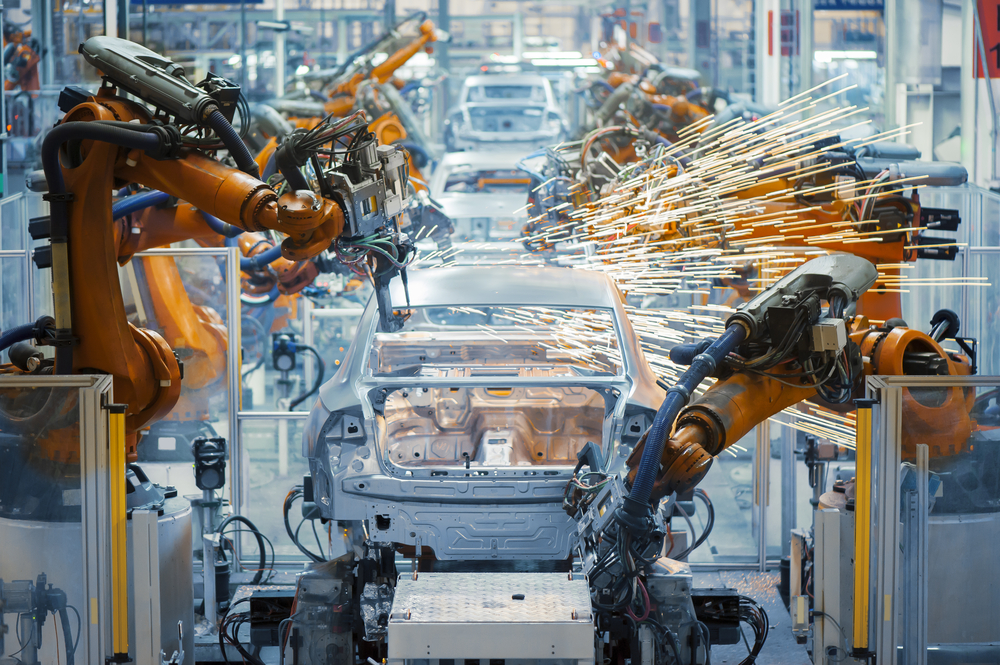

Position Control in Robotics:

- Encoders are crucial in robotics for accurate position control of robotic arms and other moving components.

- They provide real-time feedback, enabling precise movement and coordination in automated manufacturing processes.

-

CNC Machining:

- In Computer Numerical Control (CNC) machining, encoders ensure the accuracy of tool positioning and help achieve high-quality, precision machining.

- Real-time position feedback allows for adjustments to tool paths, minimizing errors and enhancing product quality.

-

Conveyor Systems:

- Encoders play a vital role in conveyor systems, ensuring precise control over the speed and positioning of items on the production line.

- This helps prevent bottlenecks, optimize throughput, and enhance overall efficiency.

-

Paper and Printing Industry:

- In printing and paper manufacturing, encoders are used to control the web tension and register of the material.

- This ensures accurate printing and cutting, reducing waste and improving the overall quality of the final product.

Resolver Cables:

-

Automotive Applications:

- Resolvers are commonly employed in automotive systems, such as steering and transmission systems.

- They provide accurate feedback on the position and speed of rotating components, contributing to vehicle safety and performance.

- Aerospace Industry:

- Resolvers are utilized in aerospace applications where reliability and precision are critical.

- They play a role in controlling various components, such as aircraft control surfaces and landing gear systems.

-

Heavy Machinery:

- Resolvers are well-suited for harsh industrial environments, making them ideal for heavy machinery like cranes, excavators, and mining equipment.

- They provide robust feedback for precise control and monitoring, contributing to safety and efficiency.

Conclusion

Encoder and resolver cables are the linchpin of modern industrial automation, ensuring the accurate measurement and control of mechanical motion. From robotics to CNC machining, and from conveyor systems to aerospace applications, these cables are indispensable in achieving optimal performance and maintaining the highest standards of precision. As technology continues to advance, the importance of encoder and resolver cables will only grow, driving innovation and efficiency across various industrial sectors.

Our Range of Encoder & Resolver Cables can be found HERE