Navigating the World of Servo Motor Cables: Understanding Design Approval

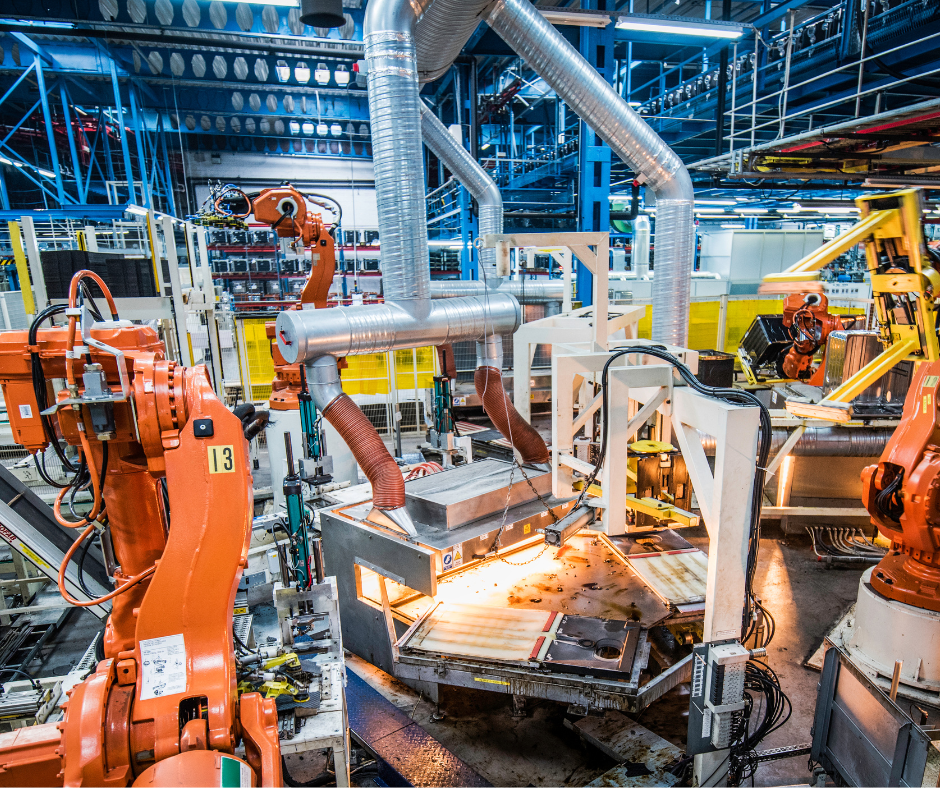

In the world of automation and robotics, servo motors play a pivotal role, translating electrical signals into precise mechanical motion. However, behind the seamless operation of these motors lies a crucial component often overlooked: servo motor cables. These cables are the lifeline that ensures efficient communication between controllers and motors, making them indispensable in any automated system. Moreover, when it comes to integrating servo motor cables into industrial settings, adhering to design approvals is paramount. Let’s delve into the significance of servo motor cables and the importance of design approval in ensuring their reliability and safety.

Understanding Servo Motor Cables:

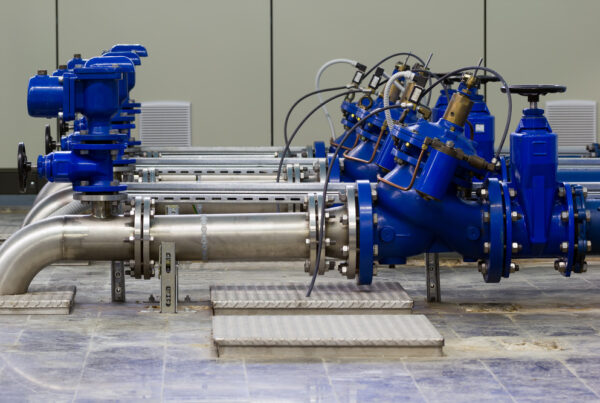

Servo motor cables serve as the conduit for transmitting power and control signals between servo drives or amplifiers and the motor itself. Unlike conventional power cables, servo motor cables are designed to handle dynamic motion, torsion, and bending, all while maintaining signal integrity. These cables typically consist of multiple conductors shielded to minimize electromagnetic interference (EMI) and ensure accurate signal transmission.

Key Features of Servo Motor Cables:

- Flexibility: Servo applications often involve repeated motion cycles, demanding cables that can withstand constant bending without sacrificing performance.

- Shielding: Shielding is crucial to prevent EMI from corrupting control signals, ensuring precise motor control and minimizing the risk of system errors or failures.

- Durability: Operating in harsh industrial environments, servo motor cables must be rugged enough to withstand mechanical stress, abrasion, and exposure to oils, chemicals, and other contaminants.

- Temperature Resistance: Servo motors can generate heat during operation, necessitating cables capable of withstanding high temperatures without degradation.

- Compatibility: Ensuring compatibility between cables and servo drive manufacturers’ specifications is essential for optimal performance and reliability.

The Role of Design Approval:

Design approval, often referred to as Desina Approval in Europe, is a certification process that verifies a product’s compliance with industry standards and specifications. In the context of servo motor cables, Desina Approval ensures that cables meet stringent requirements for performance, safety, and interoperability. This approval signifies that the cables have undergone rigorous testing and adhere to established standards, providing users with confidence in their reliability and compatibility with various servo drive systems.

Benefits of Desina Approval:

- Reliability: Desina-approved cables undergo comprehensive testing to ensure they meet stringent performance criteria, reducing the risk of system failures and downtime.

- Interoperability: By adhering to industry standards, Desina-approved cables ensure compatibility with a wide range of servo drives and motor systems, facilitating seamless integration into diverse automation applications.

- Safety: Compliance with Desina standards includes considerations for electrical safety, shielding effectiveness, and protection against environmental factors, enhancing overall system safety and reliability.

- Quality Assurance: Desina Approval serves as a mark of quality, signaling to users that the cables have been manufactured to the highest standards and are backed by thorough testing and validation processes.

Conclusion:

Servo motor cables are a critical component in automated systems, enabling precise control and motion in various industrial applications. Understanding the importance of design approval, such as Desina Approval in Europe, is essential for ensuring the reliability, performance, and safety of servo motor cables. By selecting Desina-approved cables, users can have confidence in their compatibility, durability, and adherence to industry standards, ultimately contributing to the seamless operation of automated systems and minimizing the risk of costly downtime or failures.

For the our full range of Servo Motor cables click HERE