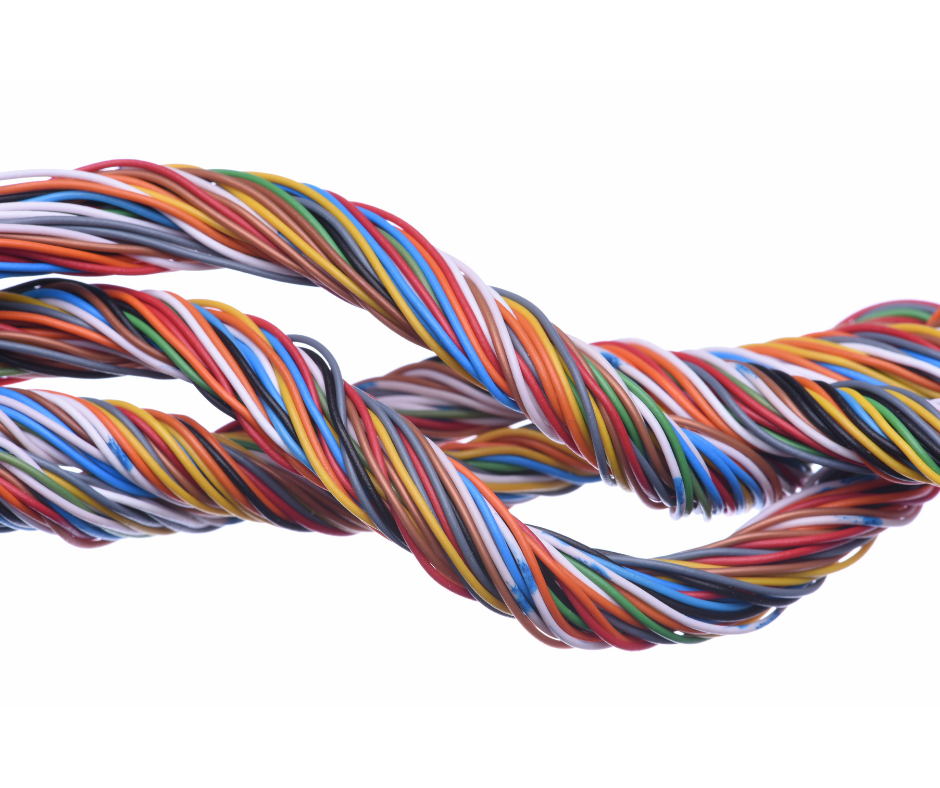

Unraveling the Wires: The Diverse Applications of Hook-Up Wires in the Electrical Industry

Introduction:

In the intricate web of the electrical industry, hook-up wires play a crucial role, often overlooked amidst the complexity of circuits and systems. These unassuming wires, with their myriad of applications, are the unsung heroes that ensure seamless connectivity and reliable transmission of electrical signals. Let’s delve into the fascinating world of hook-up wires and explore the diverse ways in which they contribute to the efficiency and functionality of electrical systems.

-

Versatility in Electronic Devices:

Hook-up wires are the lifelines of electronic devices, connecting components and facilitating the flow of electrical signals. From smartphones to laptops, and everything in between, these wires provide the necessary connectivity for the internal components, ensuring the smooth operation of our everyday gadgets.

-

Circuit Board Connections:

The intricate network of a circuit board relies heavily on hook-up wires to establish connections between various components. These wires are carefully chosen for their size, insulation, and conductivity, ensuring optimal performance and preventing signal interference.

-

Prototyping and Testing:

In the early stages of electronic device development, prototyping and testing are essential. Hook-up wires allow engineers to quickly establish connections between different components for testing purposes, enabling them to identify and rectify any issues before finalizing the design.

-

Automotive Wiring:

In the automotive industry, where reliability and durability are paramount, hook-up wires find extensive use. From engine control units to sensors and lighting systems, these wires ensure that electrical signals are transmitted efficiently, contributing to the overall safety and performance of vehicles.

-

Medical Equipment:

Precision and accuracy are critical in medical equipment, and hook-up wires play a vital role in ensuring reliable connections within devices such as MRI machines, ultrasound equipment, and patient monitoring systems. The high-quality insulation of these wires also aids in meeting stringent safety standards.

-

Aerospace Applications:

In the aerospace sector, where weight and space constraints are significant considerations, hook-up wires are indispensable. These lightweight yet robust wires contribute to the efficient functioning of avionics systems, ensuring the safety and reliability of aircraft.

-

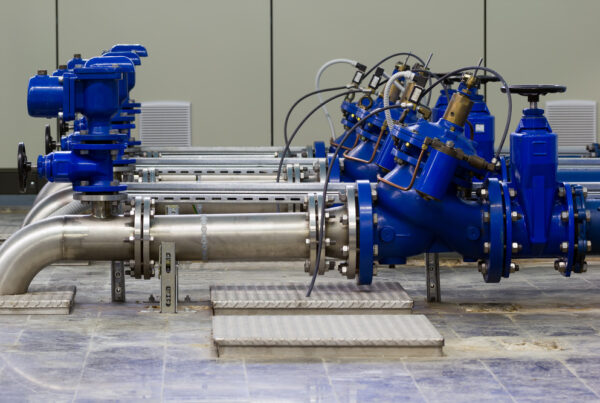

Power Distribution:

Hook-up wires are not limited to small-scale applications; they are also used in power distribution systems. These wires, with appropriate insulation and thickness, are employed in power cables, transformers, and switchgear, facilitating the seamless transmission of electricity across various components.

-

Industrial Automation:

In the realm of industrial automation, hook-up wires form the backbone of control systems, connecting sensors, actuators, and programmable logic controllers. Their flexibility and durability make them well-suited for the dynamic and demanding environments of manufacturing and processing plants.

Conclusion:

As we unravel the multifaceted applications of hook-up wires in the electrical industry, it becomes evident that these unassuming components are integral to the functionality and reliability of diverse systems. From everyday electronic devices to critical applications in aerospace and healthcare, hook-up wires continue to be the silent enablers that keep our world connected and powered. The next time you encounter a complex electrical system, take a moment to appreciate the role of these unassuming wires in making it all possible.

Our Range of Hook up wires can be viewed HERE